Looking inside Fukushima Daiichi unit 1

10 February 2015

Tepco hopes to gain a greater understanding of the location of the molten fuel in unit 1 of the damaged Fukushima Daiichi with the installation of a muon detection system. A shape-changing robot will also soon be deployed to explore within the unit's reactor.

.jpg) |

| Workers install the first detector of the muon system at unit 1 (Image: Tepco) |

Tokyo Electric Power Company (Tepco) said it is installing a muon detection system at the unit. The system comprises two measuring devices. The first was installed on the north side of the reactor building yesterday, while the second was scheduled to be put in place on the west side of the building today. Once the system is installed, it will be ready for testing, the company said.

Muons are high-energy subatomic particles that are created when cosmic rays enter Earth's upper atmosphere. These particles naturally and harmlessly strike the Earth's surface at a rate of some 10,000 muons per square meter per minute. Muon tracking devices detect and track these particles as they pass through objects. Subtle changes in the trajectory of the muons as they penetrate materials and change in direction correlate with material density. Nuclear materials such as uranium and plutonium are very dense and are therefore relatively easy to identify.

The 3-D image produced by the detectors should give a clear picture of the condition and location of the fuel in the cores of the three damaged reactor at Fukushima Daiichi.

The detector system currently being installed at Fukushima Daiichi was developed by Japan's High Energy Accelerator Research Organization (KEK). The system uses the so-called permeation method to measure the muon data. The analysis of the data is scheduled to be completed by the end of March.

Tepco's chief decommissioning officer Naohiro Masuda said, "This is a great example of how innovation and cooperation with external experts is helping us overcome the challenges and make progress toward decommissioning. I hope this will give us an opportunity to contribute to technological advancement and to share such progress with the rest of the world."

Fumihiko Takasaki, a professor emeritus at KEK, said, "As scientists, we feel we have a responsibility to use our knowledge and skills to help the decommissioning process proceed as quickly as possible."

Tepco intends to install a second muon detection system featuring different technology at unit 2 in the coming months.

Last August, Toshiba awarded a contract to US-based Decision Sciences International Corporation (DSIC) for the design, manufacture and delivery of two muon detectors.

Tepco said it will "continue to collaborate with experts inside and outside Japan to quickly and accurately obtain information on the status of the reactor cores."

Robot deployment

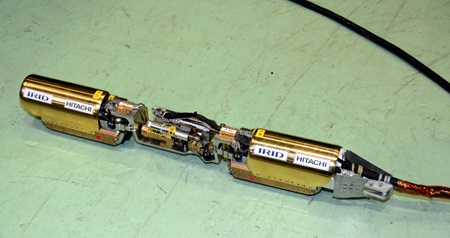

Tepco announced on 6 February that a shape-changing robot developed by the International Research Institute for Nuclear Decommissioning (IRID) and Hitachi-GE Nuclear Energy has undergone laboratory testing. It is scheduled to be deployed within the primary containment vessel of unit at Fukushima Daiichi within the next few months.

|

| The shape-changing robot (Image: IRID) |

The robot has been developed to investigate hard-to-access areas of the plant. It consists of three segments: the robot's main body and two compact crawlers. The robot can assume a long, straight shape for passing through narrow spaces, such as pipes. In tests the robot was found to be able to pass through pipes with a diameter of just 10cm. Alternatively, it can rotate its crawlers by 90 degrees in relation to its central body to assume a U-shape, with the crawlers providing better stability when travelling over flat surfaces.

The robot is 9cm in height. Depending on the position of its crawlers, it is 25cm to 64cm in length and between 6.5cm and 27cm in width. Weighing 7.5kg, the robot is operated via a 40m cable.

Robots are frequently used in nuclear and other industries to access difficult-to-reach or highly contaminated areas. At Fukushima, robots have been used to survey the damage inflicted on the plant after the 2011 tsunami and are being developed to undertake more complex tasks.

IAEA mission

A team of decommissioning experts started a nine-day mission yesterday to review Japan's plans and work to decommission the Fukushima Daiichi plant.

The 15-member team, assembled by the International Atomic Energy Agency (IAEA), was sent at the request of the Japanese government and follows two similar missions in April 2013 and November-December 2014.

Team leader Juan Carlos Lentijo, director of the IAEA's nuclear fuel cycle and waste technology division, said: "Decommissioning the Fukushima Daiichi nuclear power station is a very challenging and complex task. Through this and the previous missions, the IAEA brings a depth of experience of its own and from our member states to support Japan's work to meet this challenge. In addition, our work will enable the international community to learn from the accident and the decommissioning process."

Researched and written

by World Nuclear News