First look in unit 3's pond

10 May 2011

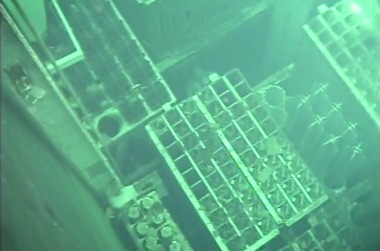

Debris litters the fuel pond of Fukushima Daiichi 3, a remote camera inspection has shown. Elsewhere on site work is underway for long-term cooling of damaged reactor cores.

|

|

| A video still of unit 3's fuel pond as compared to one of unit 4's (bottom). Unit 3's contains 514 fuel assemblies, while unit 4's contains 783, plus 548 taken from the reactor core for maintenance in November 2010 |

The video check by Tokyo Electric Power Company (Tepco) is the latest in the firm's efforts to take full stock of the situation at the wrecked nuclear power plant and make good its stabilisation efforts.

Fuel stored in the pond was not visible beneath a mass of steel beams, concrete, dust and rebar from the explosive destruction of the reactor building roof. Concrete dust appeared thick on the surface of flat objects and specks of dust were circulating in the warm water of the pond.

A similar check of unit 4's fuel pond had not shown anything like the same level of debris, leading to the tentative conclusion that 'fuel integrity had been maintained as a whole' in unit 4. Tepco did not announce any assessment of the fuel in unit 3's pond with the video.

The fuel ponds of these reactor units were a major concern earlier in the Fukushima crisis. Unit 3 is using external power for top-up via the usual cooling and cleanup system, while unit 4 requires direct spraying from a concrete pump truck. Hydrazine is being injected along with water at both units to inhibit corrosion.

Getting inside

The installation of air filters has allowed workers to re-enter unit 1 with initial goals to install a new water level gauge for the reactor system as well as a longer-term cooling circuit. Tepco hopes to achieve the status of 'cold shutdown', where the reactor is at less than 100ºC, although this technical status is less meaningful than at an undamaged reactor.

Filters reduced radioactivity in the air from 4.8 to less than 0.02 becquerels per cubic centimetre between April 26 and 7 May. Seven Tepco workers, plus two from the Nuclear and Industrial Safety Agency and 21 contractors passed through the reactor building airlock to survey radiological conditions ahead of further construction work.

Changes are also coming for the coolant system of unit 3. Instead of injecting fresh water via fire extinguishing lines directly into the reactor vessel Tepco will connect a new more robust line to the usual feedwater system.

Researched and written

by World Nuclear News