Mühleberg plant enters permanent decommissioning stage

18 September 2020

The Swiss Federal Nuclear Safety Inspectorate (ENSI) has announced that the operating licence of the Mühleberg nuclear power plant (KKM) has been replaced with a decommissioning order issued by the Federal Department of Environment, Transport, Energy and Communication (DETEC). The single unit 373 MWe boiling water reactor began operations in 1972.

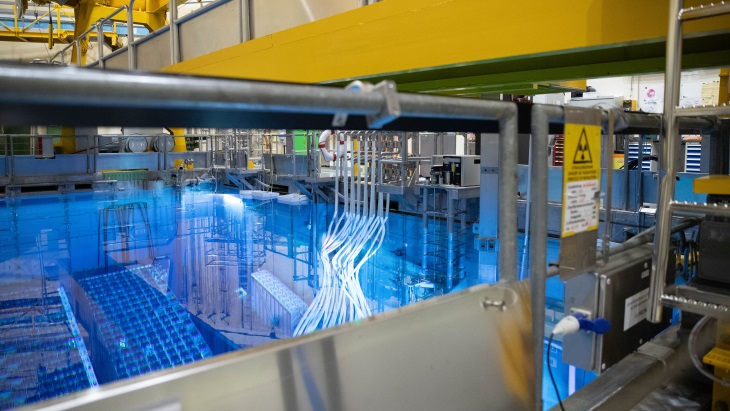

Fuel rods at Mühleberg nuclear power plant (Image: BKW)

Fuel rods at Mühleberg nuclear power plant (Image: BKW)

The plant was shut down in December 2019, but has only been considered permanently out of service since 15 September this year, and its operating licence has now been replaced by the decommissioning order, ENSI said.

In a separate statement, BKW said the milestone had been reached as planned - around nine months after the final cessation of service operations on 20 December 2019 - and that the coronavirus pandemic had so far had no impact on the schedule.

"BKW is doing pioneering work with the shutdown of the KKM. It is the first time that a power reactor is being dismantled in Switzerland. The shutdown will take around 15 years and will be completed in 2034. BKW mainly carries out the work with its own employees who have extensive knowledge of the system and valuable specialist knowledge," BKW said.

"Service providers and experts with international experience in the dismantling of nuclear power plants are called in for highly specialised one-off tasks. The most important of these orders have already been awarded and the necessary external services have been secured. The financing of the decommissioning and disposal of the radioactive waste is also ensured. BKW pays the necessary costs in full," it added.

Staged process

ENSI explained the difference between the final cessation of power operation (EELB by its German acronym) and final decommissioning (EABN).

"In Switzerland, the EELB is defined as the point in time at which electricity production ceases and the nuclear power plant is finally shut down. According to the ENSI-G17 guideline, EABN means the so-called final cessation of normal operation of a nuclear installation. With the final decommissioning, the owner of the nuclear installation is obliged to decommission," it said.

"KKM is only considered to be finally decommissioned when all the fuel elements have been transferred from the reactor to the storage pool and the measures required to establish safe technical post-operation (ETNB) have been implemented."

The most important measures in this context were changes to the system so that the fuel storage pool can be cooled "independently and redundantly", ENSI said. This work was carried out on the basis that the plant’s operating licence was still valid, because the still existing operating and safety systems were required to dissipate the residual heat from the fuel elements during the establishment of the technical post-operation phase. In addition and in contrast to the decommissioning work, this work had to be carried out "promptly and absolutely" in order to bring the system to a long-term safe condition after the final cessation of power operation.

The preparatory measures were therefore carried out under the operating licence and in parallel with work to establish technical post-operation - and thus before the final decommissioning. This was possible because the preparatory measures are subordinate safety-relevant decommissioning work which, in DETEC's opinion, may be carried out from the point at which power operation has ceased.

KKM will be dismantled in three decommissioning phases (SP).

SP1 lasts until all the plant’s fuel assemblies have been removed, which expected in 2024. ENSI approved SP1 in June this year. SP2 ends with the lifting or clearing of controlled zones, probably around 2030. SP3 includes work to demonstrate that the system is no longer a source of radiological hazard, which is scheduled for 2031.

The conventional demolition of the plant will be regulated according to a second DETEC decommissioning order.

On schedule

BKW said that, in addition to the measures to implement the independent cooling of the fuel storage pool, further work has been carried out in the reactor building over the last few months. In the reactor building, the lid of the containment vessel and the insulating hood of the reactor pressure vessel were dismantled. The control rods, with which the output of the reactor was controlled during operation, and their drives were expanded.

The construction of facilities that will later be used to dismantle the core internals is currently in progress. These include, for example, lifting platforms and cranes.

The preparatory measures for decommissioning have been "pushed ahead" in the machine house, BKW said. For example, the turbines will be removed and transported to a specialist company in Sweden, where they will be melted down. This company will separate the radioactive waste from the recyclable steel.

In addition, over 40 systems in the turbine hall that are no longer needed have already been taken out of operation. This includes water-steam cycle systems, such as the condensate system, the feed water system and the main steam lines, but also the auxiliary systems for the turbines such as the turbine lubricating oil system.

Additional systems will be taken out of service and dismantled over the next few months. The generators, which weigh around 420 tonnes, will also be removed. For this, an additional heavy-duty mast has to be installed in the turbine hall. And finally, the establishment of systems in which the material can be cleaned and cleared before it is removed is also progressing, it said.

Researched and written by World Nuclear News