Metallic fuel under consideration for NuScale SMR

.jpg)

Lightbridge fuel uses a helically-twisted shape and unique metallic composition which the company says can significantly reduce fuel operating temperatures, improve the fuel's structural integrity and enhance its response to abnormal events. Enfission - a joint venture of Lightbridge Corporation and Framatome - was set up in January 2018 to commercialise nuclear fuel assemblies based on this technology.

The MoU between NuScale and Enfission will see the two parties work together to develop research and testing programmes to explore the application of Enfission fuel technology, which they say is "well-suited" for the natural circulation design of NuScale's SMR. The advanced fuel rod design is expected to increase core performance, extend core life, reduce refuelling outages and offer reduced levelised cost of electricity, they said.

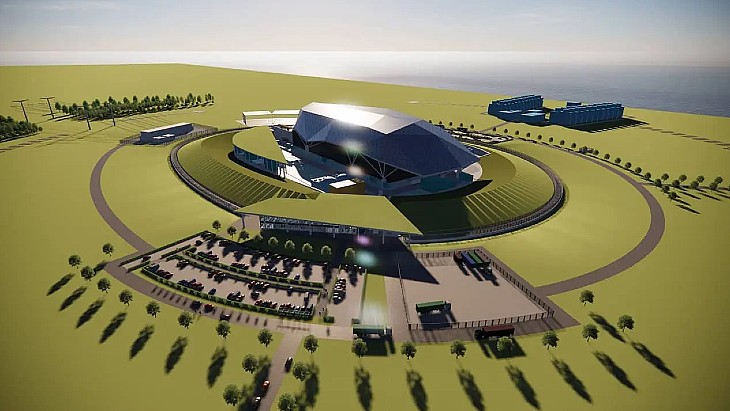

NuScale's SMR design features the factory-fabricated, self-contained NuScale Power Module, with a gross capacity of 200 MWt or 60 MWe. Based on pressurised water reactor technology, the scalable design can be used in power plants of up to 12 individual modules. A US Nuclear Regulatory Commission design certification review of the technology is scheduled for completion in September 2020. A demonstration NuScale SMR is projected to be operational by 2024 at the US Department of Energy's Idaho National Laboratory (INL) site. This is to be followed by a 12-module NuScale plant, owned by Utah Associated Municipal Power Systems and operated by Energy Northwest.

Framatome in 2015 signed an agreement with NuScale to manufacture fuel assemblies for its SMR based on conventional ceramic uranium dioxide fuel and provide testing and analyses needed for its Nuclear Regulatory Commission design certification application.

"The addition of Enfission's Lightbridge Fuel into the equation further solidifies this relationship and will provide future flexibility on fuel types depending on the reactor demands," the companies said.

_92619.jpg)

_84504.jpg)

..._58412.jpg)