Russia notes progress with fast reactor technology

Russia has reached two more milestones in its endeavour to close the nuclear fuel cycle. Mashinostroitelny Zavod (MSZ) - part of Russian nuclear fuel manufacturer TVEL - has completed acceptance tests of components for its ETVS-14 and ETVS-15 experimental fuel assemblies with mixed nitride fuel for the BREST and BN fast neutron reactors. MSZ has also announced the start of research and development work on the technical design of the "absorbent element" of the core of the BREST-OD-300 reactor.

A Russian government decree published earlier this month indicates the country plans to construct 11 new nuclear power reactors by 2030 - including two BN-1200 sodium-cooled fast neutron reactors. The BN-1200 units are to be built at the Beloyarsk and South Urals nuclear power plants.

The decree also approves building a facility to produce high-density U-Pu nitride fuel and the construction by 2025 of the BREST-OD-300, which is part of Russian state nuclear corporation Rosatom's 'Proryv', or Breakthrough, project to enable a closed nuclear fuel cycle. The ultimate aim is to eliminate production of radioactive waste from nuclear power generation. The Breakthrough project comprises a fuel production/refabrication module for production of dense uranium plutonium (nitride) fuel for fast reactors; a nuclear power plant with a BREST reactor; and a used fuel retreatment module.

TVEL announced in October last year that MSZ had fabricated prototypes of ETVS-12 and ETVS-13 experimental fuel assemblies for the Brest-OD-300 lead-cooled fast reactor system, which was developed by the N A Dollezhal Research and Development Institute of Power Engineering, or NIKIET.

Assembly of the ETVS experimental fuel assemblies will be conducted by Siberian Chemical Combine, another TVEL subsidiary. Later, the ETVS-14 and ETVS-15 will be installed for pilot operation in the BN-600 unit at the Beloyarsk nuclear power plant.

MSZ said it has this year made components for the four assemblies - ETVS-12 to ETVS-15 - and that next year it will do the same for six more - ETVS-16 to ETVS-21.

It will produce the absorbent element, or PEL by its Russian acronym, for BREST-OD-300, on behalf of VNIINM - the AA Bochvar Institute of Inorganic Materials. Rosatom awarded MSZ the RUB24 million ($371 million) contract for this work on 19 August and it is to be completed by 1 December. TVEL describes PEL as an element of the reactor core designed to control reactivity using a neutron-absorbing material. VNIINM is developing the nuclear fuel for BREST-OD-300.

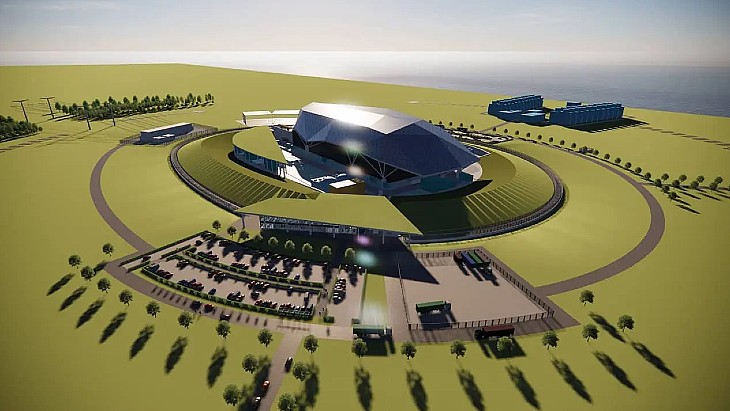

A nuclear power plant with BREST-OD-300 is to be part of a pilot energy complex, or ODEK, under construction at the site of the Siberian Chemical Combine in the Tomsk region.

Separately, Rosatom announced that the World Association of Nuclear Operators (WANO) has started a planned peer review of the Beloyarsk nuclear power plant, which is in the Sverdlovsk region of central Russia. It has two shut down reactors and one in commercial operation - Beloyarsk 3. Unit 4 of the plant was connected to the national grid in December last year. The 789 MWe BN-800 Beloyarsk 4 is fuelled by a mix of uranium and plutonium oxides arranged to produce new fuel material as it burns. Its capacity exceeds that of the world's second most powerful fast reactor - 560 Mwe Beloyarsk 3.

The planned Beloyarsk 5 BN-1200 will use larger fuel elements than the BN-600 and BN-800 and have a simplified refuelling procedure. Russian nuclear engineering company OKBM Afrikantov is developing the BN-1200 as a next step towards future reactor designs, commonly known as Generation IV.

The WANO team consists of 26 international experts, headed by the deputy chief engineer of the South Ukraine nuclear power plant, Vladimir Bandurko. The team - with representatives from Bulgaria, the Czech Republic, France, Hungary, Iran, Japan, Mexico, Slovakia and Ukraine, as well as from WANO's Moscow Centre, and the Balakovo, Kalinin, Rostov and Smolensk nuclear power plants.

Rosatom said the team will identify areas for improvement in activities such as administration, operation, maintenance, engineering support, radiation protection, improvement of production and service experience, chemicals management, training and the qualification of personnel, fire safety and emergency preparedness. The review is to be completed by 2 September.

Researched and written

by World Nuclear News

_92619.jpg)

_84504.jpg)

_66488.jpg)