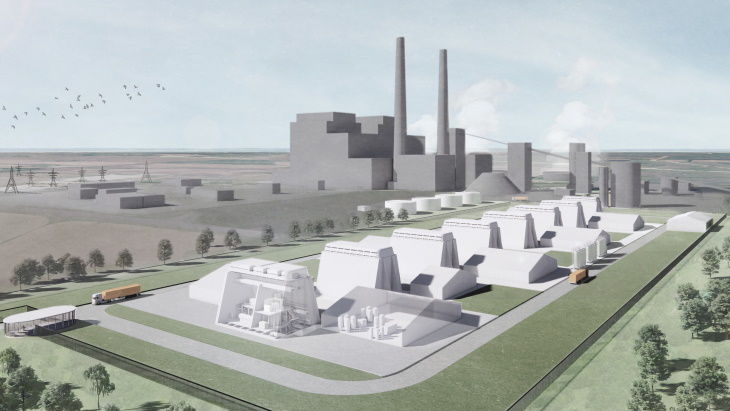

The design company is working with non-profit organisation TerraPraxis on its Repowering Coal initiative, which aims to design a process to repower two terawatts of coal generating capacity via a fast, repeatable system resulting in carbon negative plants that are cheaper to operate than before.

"Replacing coal boilers with advanced modular reactors (AMRs) allows the use of existing infrastructure for clean electricity generation and a fast, low-risk path to decarbonising global power generation," according to Bryden Wood.

"Unlike other proposed solutions, repowering coal plants offers robust political viability because it preserves jobs, local economies and existing, high-value infrastructure investments."

The company said the initiative will deliver a substantial portion of the clean electricity required to achieve Net-Zero by 2050 by replacing coal-fired boilers at existing power plants with AMRs. Such reactors will be ready for deployment by 2027, by which time the digital platform will be sufficiently developed to realise carbon savings at a massive scale by the end of this decade.

Bryden Wood is working with TerraPraxis, the Massachusetts Institute of Technology, University at Buffalo, Microsoft and KPMG to create a new building system to standardise and optimise the following key elements: all processes, including procurement, investment and approval; building and engineering systems; design, manufacture, assembly and operation; and interactions between different supply chain organisations to enable greater collaboration.

According to Bryden Wood, a standardised but customisable heat transfer and storage system allows the new, small nuclear systems to "plug in" to existing coal plant infrastructure. Existing plants have enormous value in terms of established markets for their power, grid connections, access to cooling water and experienced personnel necessary for the generation and distribution of power.

Converting these plants to run on AMRs will deliver a capital cost saving of 28%-35% (compared with a new nuclear plant) and a 9%-28% reduction in the levelised cost of energy.

Standardisation will address the differing requirements for a wide variety of AMRs, site layouts, and energy and heat demand, it notes. The component-based design enables the plant to be reconfigured and expanded to accommodate different numbers of AMRs.

New digital infrastructure will enable design knowledge to be embedded in the building systems and design tools so that all parties can share progress and results in real time across all projects, Bryden Wood said. New algorithmic design tools are being created to: assess coal plant viability for AMR replacement; create initial concepts using a design configurator in just days; and produce detailed design outputs for manufacturing. The structural components, it said, can then be mass produced by existing and new manufacturers and assembled on-site by non-nuclear specialists.

Initially, the project will launch in the USA but is designed to be rolled out worldwide and to attract customers and supply chain partners to re-engineer coal plants in all locations.

"We're building the market for AMRs at the same time as the product itself is being developed," said Bryden Wood co-founder Martin Wood. "The digital tools we're creating will enable us to have a huge number of projects, across multiple sites, ready to go as soon as the reactors are approved. Speed and agility have never been so important."

TerraPraxis co-founder Eric Ingersoll added: "This ambitious project will design a process to repower the world's coal fleets via a fast, repeatable system resulting in carbon negative power plants that are cheaper to operate than before and ensure continuity for communities reliant on these plants for energy and jobs."

_23621.jpg)

_63865.jpg)

_18570.jpg)