Milestones in construction of Chinese plants

![]() First concrete has been poured for the second unit at the Fangjiashan nuclear power plant in Zhejiang province. Meanwhile, the first massive module for the initial Sanmen AP1000 unit has been hoisted into place.

First concrete has been poured for the second unit at the Fangjiashan nuclear power plant in Zhejiang province. Meanwhile, the first massive module for the initial Sanmen AP1000 unit has been hoisted into place.

First concrete has been poured for the second unit at China National Nuclear Corp's (CNNC's) Fangjiashan nuclear power plant in Zhejiang province. Meanwhile, the first massive module for the initial Sanmen AP1000 unit has been hoisted into place.

The Fangjiashan project will see two CPR-1000 reactors with a combined capacity of 2160 MWe constructed near the existing Qinshan plant. First concrete for the first unit at the Fangjiashan plant was poured in December 2008. The dates scheduled for the start of their commercial operation are December 2013 and October 2014.

The region of China in which the plant is being constructed borders the Shanghai municipality on the country's east coast but is short of energy resources to sustain its population of over 47 million.

Nuclear power production started at Qinshan in 1994 with the operation of a relatively small 279 MWe domestically-designed reactor. Four more units - two of 610 MWe and two of 665 MWe - started up between 2002 and 2004, and another two of 650 MWe are under construction at the moment. By 2014, when the adjacent Fangjiashan units start, the 'Qinshan Base' will boast nine reactors and around 6300 MWe of nuclear capacity.

CNNC, which has the task of implementing the mass deployment of CPR-1000s, earlier said that the Fangjiashan project would have 'far-reaching significance' and an 'irreplaceable role of demonstration' for future nuclear plans. The total cost of the two-unit Fangjiashan plant is put at 26 billion yuan ($3.8 billion).

Heavy lifting at Sanmen

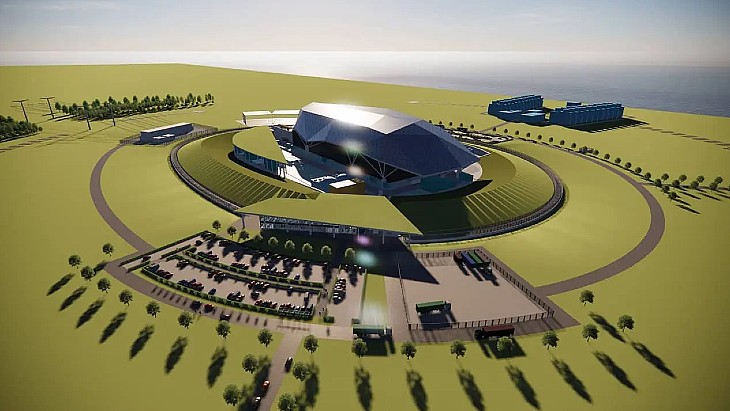

.jpg) |

| The first module is hoisted into position at Sanmen (Image: SNPTC) |

Meanwhile, CNNC has also announced that the first of the CA20 nuclear island modules for the two AP1000 reactors under construction at the Sanmen nuclear power plant, also in Zhejiang province, has been successfully hoisted into place.

An LTL-2600B-type crawler crane - the world’s largest such crane - was used to hoist the CA20 module, which weighs some 840 tonnes, into position. The module comprises plant and equipment for used fuel storage, transmission, the heat exchanger and waste collection, among other things. The CA20 module - measuring 20 metres long, 14 metres wide and 20 metres high - is the largest component to be used in the construction of the Sanmen AP1000 units.

More than 50 other modules to be used in the reactors' construction weigh more than 100 tonnes, while 18 weigh in excess of 500 tonnes.

The first Sanmen unit - being built by Westinghouse and its partner Shaw - is expected online in August 2013 and should be the world's first AP1000 in service. The second Sanmen reactor should start up about one year later, while another four AP1000s could also be built there. A second twin-AP1000 site at Haiyang in Shandong province is also moving forward, with first concrete on the first unit expected in September.

Under a 'self reliance' program, the AP1000 is to be mass produced and deployed in China under the leadership of the State Nuclear Power Technology Corporation (SNTPC).

Shandong Nuclear Power Equipment Manufacturing Co, which is producing the AP1000 components in China, said that in May it completed and shipped the first CA20 module for Sanmen 1. The company recently received the N-Stamp accreditation by the American Society of Mechanical Engineers for its nuclear-grade steelwork.

As part of China's plans to deploy AP1000s and future derivatives on a mass scale, Shandong is to specialise in the manufacture of large components like this, as well as pre-assembled modules.

For the first two AP1000s the supply of reactor pressure vessels, a key supply-chain issue, has been contracted to Doosan Heavy Industries of South Korea by Westinghouse and Shaw. Chinese firms will supply these for the second units at each site: China First Heavy Industries Corp for Sanmen, and Shanghai Electric (SEC) for Haiyang. Other firms are preparing to bid for subsequent units.

_92619.jpg)

_84504.jpg)

_66488.jpg)