Three UK sites in running to host first Rolls-Royce SMR factory

.jpg)

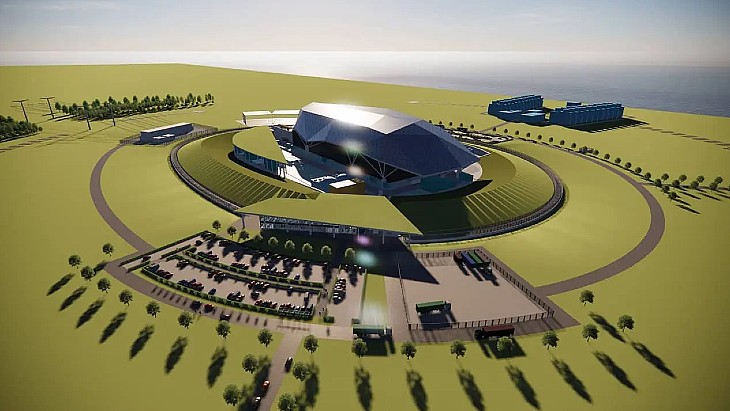

The final shortlist comprises: the International Advanced Manufacturing Park (IAMP) in Sunderland, South Tyneside in North East England; Teesworks, Redcar, in Teesside also in North East England; and Gateway, Deeside, in North Wales.

Rolls-Royce SMR said the selection of the three potential sites was made following a series of visits and further assessments of each site's suitability to host the heavy pressure vessels factory.

The factory - costing GBP100-200 million (USD121-242 million) - is expected to be around 23,000 square metres in size and will create more than 200 permanent roles.

"This is part of the process to build the first of at least three factories that will manufacture components for a fleet of small modular reactors and will present an incredible opportunity for a region of the UK," said Rolls-Royce SMR CEO Tom Samson. "Our power stations will be built in British factories situated in the north of England or Wales and will generate tens of thousands of long-term highly skilled jobs - accelerating regional economic growth."

In July, Rolls-Royce SMR announced six potential locations for the factory, picked from more than 100 submissions from local enterprise partnerships and development agencies. They were: Sunderland in Tyne and Wear, Richmond in North Yorkshire, Deeside in Wales, Ferrybridge in Yorkshire, Stallingborough in Lincolnshire and Carlisle in Cumbria. In October, two more locations - Deeside and Teesworks - were added after the sites met the shortlist criteria.

The company will decide on the location early next year after final evaluations and detailed assessments are made against the requirements and criteria for the factory, which will manufacture and assemble some of the largest and most complex components of the Rolls-Royce SMR power plant.

"To ensure commercial processes move in parallel, negotiations will be initiated when Rolls-Royce SMR has entered formal discussions on deployment with the government," it added.

The other two factories will manufacture civils modules and mechanical electrical and plumbing (MEP) modules - which will be transported to sites and assembled into a nuclear power plant.

"All of the initial responses will be retained and separate selection processes will be run for the following two factory locations (civils modules and MEP modules)," Rolls-Royce SMR said.

The Rolls-Royce SMR design was accepted for Generic Design Assessment review in March with the UK's Department for Business, Energy and Industrial Strategy asking the Office for Nuclear Regulation along with the environment regulators for England and Wales to begin the process.

To minimise the construction phase of the programme, the Rolls-Royce SMR is fully modularised with the reactor, about 16 metres by 4 metres, able to be transported by road, rail or sea. Targeting a 500-day modular build, the firm says this concept minimises the onsite time and effort required to construct and build the plant, with about 90% of manufacturing and assembly activities carried out in factory conditions.

In November, Rolls-Royce SMR announced that a siting assessment review had identified a range of existing nuclear power plant sites in the UK that could potentially host its SMRs, with four sites owned by the Nuclear Decommissioning Authority prioritised.

_92619.jpg)

_84504.jpg)

_79311.jpg)