Turbine equipment for Akkuyu 1 delivered

.jpg)

The total mass of the cargo batch exceeded 1000 tons. The heaviest piece of equipment delivered was the turbine generator stator, which weight more than 430 tons and is 12 metres long. Cargo of that size requires special preparation for its unloading and subsequent transportation. The weight of other delivered items is 260 tons for the turbine generator rotor, 240 tons for the lower casing and 147 tons for upper casing of the low-pressure cylinder.

Using a large crane, the turbine plant components were transferred to self-propelled modular transporters and moved to temporary storage areas at the Akkuyu construction site. The unloading operation of all the components lasted seven days.

"The turbine generator stator is the heaviest nuclear power plant equipment, so its transportation is subject to particularly strict requirements," noted Sergey Butckikh, first deputy CEO and director of NPP construction at Akkuyu Nükleer. "In the near future we expect the arrival of another low-pressure cylinder body and a noise-protective turbine enclosure. This year we are planning to start installation of the main process equipment of the unit 1 turbine building."

Representatives of Turkey's nuclear regulatory authority, the equipment supplier AAEM LLC, and Akkuyu Nükleer participated in the acceptance of the completed equipment at the manufacturing plant prior to its shipment by sea to the construction site.

Since 2017, AAEM - a joint venture between Atomenergomash JSC and GE Steam Power - has been performing the contract for the supply of steam turbine package equipment for the turbine halls at the Akkuyu plant. AAEM is responsible for the engineering, design, and supply of the equipment. The main turbine-generator plant equipment, including the half-speed Arabelle turbine, GIGATOP four-pole generator and condenser vacuum system equipment will be manufactured by GE Steam Power. The pumps, heat-exchange and other auxiliary equipment will be mainly manufactured by Atomenergomash subsidiaries.

AAEM delivered the first high and intermediate-pressure rotor for the Arabelle steam turbine of Akkuyu 1 to the construction site in April 2021.

The rotor was manufactured by GE Steam Power at its Belfort factory in France with the support of AAEM four months ahead of schedule. The rotor took 16 months to manufacture. It is 12 metres long and weighs 107 tons. In total, four half-speed Arabelle steam turbines will be installed at the Akkuyu plant, one at each unit. Each turbine comprises three modules: one high and intermediate-pressure module and two low-pressure modules. The overall length of the turbine-generator will be around 60 metres.

Earlier this month, Akkuyu Nükleer announced that installation had been completed of the main equipment within the reactor building of Akkuyu 1. In addition to the reactor pressure vessel, the four main circulation pumps, the four hydraulic accumulators of the emergency core cooling system and the four steam generators have now been installed.

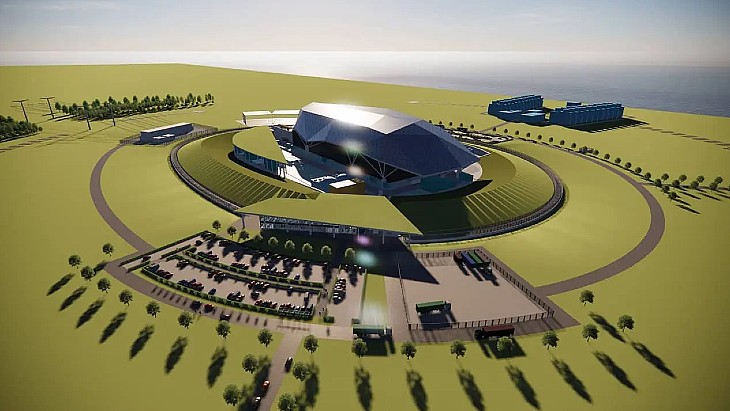

Rosatom is building four VVER-1200 reactors at Akkuyu, under a so-called BOO (build-own-operate) model. Construction of the first unit began in 2018, with start up planned for 2023. The 4800 MWe plant is expected to meet about 10% of Turkey's electricity needs.

_92619.jpg)

_84504.jpg)

_66488.jpg)