Karachi 2 pressuriser completes tests

.jpg)

China National Nuclear Corporation (CNNC) said the pressuriser - manufactured by Harbin Electric Corporation - completed the test in Pakistan on 16 October. The test, it said, "is a key node for examining its overall strength, tightness and the quality of the main welding seam".

The major component - together with the reactor pressure vessel, the main pumps and the heavy-gauge piping between them - makes up the primary coolant circuit of the pressurised water reactor. The pressuriser is designed to maintain the pressure within that circuit.

CNNC said the hydraulic pressure test proved the pressuriser meets design standards, "marking a solid step in the process of exporting China's independently researched and developed third-generation nuclear power technology".

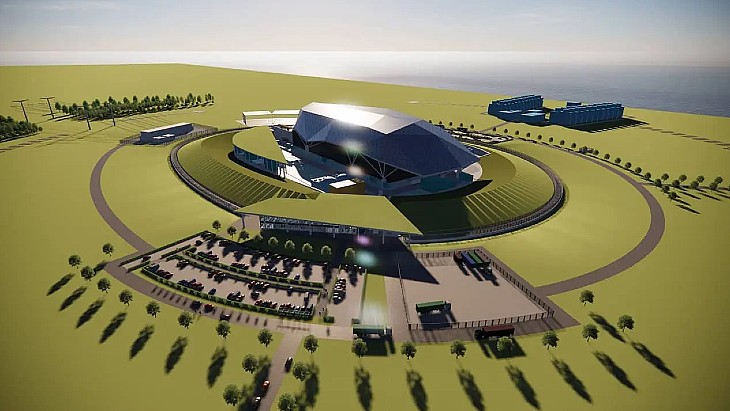

Karachi 2 and 3 are the first export of China's Hualong One design, with construction of unit 2 beginning in 2015 and unit 3 in 2016. The units are scheduled for commercial operation in 2021 and 2022, respectively.

In addition to the two units under construction at Karachi, four Hualong One units - also known as HPR1000 - are being built in China. Fangchenggang 3 and 4 and Fuqing 5 and 6 are all expected to enter commercial operation in 2019-2020.

_92619.jpg)

_84504.jpg)

_50521.jpg)