As the industry edges closer to bringing these exciting new technologies to life, integrating sophisticated data systems and emerging digital and artificial intelligence (AI) technologies across all phases of the advanced nuclear technologies lifecycle is critical to the success of the nuclear renaissance.

However, deploying small modular reactors (SMRs) and advanced modular reactors (AMRs) is a more complex challenge than big nuclear due to several interrelated factors:

- There is no vertically integrated utility model for advanced nuclear technologies (ANT), requiring the creation of an ecosystem of reactor vendors, developers, engineering, procurement, and construction (EPC) organisations, and programme integrators, as well as future operators.

- A core economic promise of ANT reactors is that they are designed for fleet standardisation to unlock economies of volume. This tension between protecting global IP and local design needs, makes data sharing more sensitive.

- The supply chain for ANT is underdeveloped, requiring specialised materials and new manufacturing and modularisation techniques, leading to potential delays and ballooning costs.

- ANT demands a workforce with specialised training and expertise, which is at risk based on the current skills gap in nuclear.

So how can we transform the fragmented nature of this effort into greater levels of coordination and data sharing so that the roll-out of SMRs and AMRs matches ambition? And, just as importantly, how can we embed a sustainable, data-driven approach so that an engineer 50 years from now can swiftly access today's information to make faster decisions?

Dual-purpose data: Meeting today's and tomorrow's needs

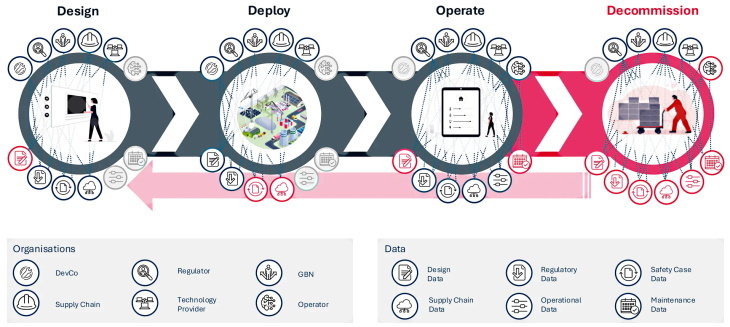

The successful deployment and operation of SMRs and AMRs hinges on data it can trust. And going beyond addressing the immediate needs of today's nuclear workforce, developing integrated digital ecosystems that support the entire lifecycle of nuclear projects. These solutions should enhance both day-to-day operations and the unmet needs of the future.

For example, to manage operational outages safely and efficiently, operators must review and update safety cases, maintenance schedules, and designs. Each of these data sets evolves as plant modifications are introduced during construction and commissioning. This is why managing configuration information digitally - not through documents - is essential for rapid design approvals, swift deployment, and reliable operations.

(Image: PA)

The journey towards a fully data-driven future will unfold in waves, each requiring targeted action and collaboration. The following recommendations represent fundamental, no-regret actions that should be implemented today - while keeping the ultimate end-state and long-term objectives firmly in sight.

Build industry consensus and transform data culture through collaborative, cross-functional sustainable data management

Champion cross-functional teams, build awareness of data's value, and create forums (consortia and working groups) that bring together reactor vendors, developers, EPCs, regulators, and future operators. This ensures everyone sees data as a collective asset rather than an isolated responsibility.

Alongside this cultural shift, there will be a need to evaluate, select, or combine one of four data management models - ranging from a centralised entity that owns and manages data to fully decentralised ownership and exchange. Each model involves trade-offs around security, innovation, stakeholder trust, and investment, so a clear, industry-wide consensus is crucial.

Why it matters: Data challenges are often people challenges. Fostering a culture that recognises the centrality of data - and the shared responsibility for it - encourages more open collaboration across a complex, multi-organisation value chain. By aligning on a suitable business model for data management, you minimise duplication, enhance trust, and ensure consistent practices.

Establish robust data standards and governance

Develop common data taxonomies, regulatory frameworks, and incentives for data-sharing to ensure consistency, security, and trustworthiness across the reactor lifecycle. Standardise reporting formats and incentivise widespread data-sharing practices to reduce administrative burden. Map how each data type and its intrinsic value evolves - from Computer-Aided Design (CAD) models and specifications during design, to construction logs and procurement data, to real-time operational metrics and incident reports during operations so you can prioritise what matters most at each stage. Finally, invest in data quality management and validation processes to maintain accuracy and consistency over decades, ensuring the data remains reliable throughout the plant's lifecycle.

Why it matters: Ultimately, knowing you can trust the data unlocks progress. Trustworthy data underpins effective decision-making throughout the entire lifecycle, from design and construction to operation and decommissioning. Inconsistent formats and fragmented ownership lead to silos and inefficiencies. For example, while CAD models and supplier details drive accurate builds early on, day-to-day performance metrics and maintenance logs become vital for safe, efficient operations years later. By recognising these shifts, you can streamline how data is collected, stored, and validated over time.

Implement secure, scalable, and future-proof digital ecosystems

To fully harness the power of data and enable seamless collaboration across the value chain, the industry must adopt secure, scalable digital platforms that facilitate real-time data exchange among developers, regulators, and operators. Cybersecurity measures should be built in from the outset, safeguarding intellectual property and safety-critical information, while still allowing for the level of data-sharing necessary to drive innovation. Equally important is planning for data longevity: robust archival and retrieval processes will ensure that today's information remains accessible for decades to come, empowering future engineers to make informed decisions quickly and confidently.

Why it matters: ANT projects will generate vast amounts of diverse data, and their success depends on harnessing it effectively. Today, for example, operational data storage can reach hundreds of terabytes per year for a single plant. Given the need to share this data across multiple organisations and preserve it for future analysis, we must design our approaches and digital systems such that future generations can talk to historical data without the issues experienced today.

Leverage AI technologies for knowledge capture and decision support

Build integrated databases that unite structured information (such as CAD models and logs) with unstructured data (like video recordings and operator insights). By employing generative AI, the industry can create interactive, context-aware tools that let future engineers "talk" to historical data - effectively consulting past expertise.

Our work with the UK's Nuclear Decommissioning Authority (NDA) and Sellafield included developing and deploying DANI - NDA and Sellafield's first generative virtual assistant. Sellafield engineers can now ask DANI what safety cases will be impacted by the introduction of an asset or configuration - detective work that once required up to a year, can now be accomplished in seconds.

Finally, align on suitable business models and IP-sharing frameworks to protect proprietary information while promoting broader industry learning and advancement.

Why it matters: AI can transform how nuclear knowledge is captured, stored, and accessed - helping to automate routine tasks, optimise resource allocation, and streamline regulatory compliance.

Adopt an adaptive, evolutionary approach to complexity to avoid premature decisions

Adopt an iterative approach that blends systems engineering with prototyping, establishing clear but flexible objectives from the outset. Leverage real-time performance metrics and continuous feedback loops to refine designs, construction methods, and operational practices as new information becomes available. By making decisions only when sufficient data exists to mitigate risks, the industry can effectively manage the complexities and uncertainties inherent in first-of-a-kind projects.

Why it matters: First-of-a-kind nuclear projects carry both inherent uncertainty and significant complexity. Trying to finalise all design and operational decisions too early can lead to missteps and costly rework.

As we continue to refine these approaches and solutions, it's clear that no single organisation can solve these complexities alone. Strategic partnerships across the entire nuclear sector are essential if we are to navigate regulatory, technical, and operational challenges while delivering on the mission. By integrating advanced digital tools and AI-driven solutions into today's planning, we can transform SMRs and AMRs into intelligent enterprises - leading the way in safety, efficiency, and innovation. By leveraging these technologies now, the nuclear industry could become one of the most forward-thinking sectors in the world.

Derreck Van Gelderen

Strategy, data, and AI expert, PA Consulting

Matt Leedham

Nuclear expert, PA Consulting

_50521.jpg)