MoltexFLEX publishes research on graphite interaction with molten salt

The research was conducted at MoltexFLEX's laboratory in Warrington and at Manchester University, which are both in northwest England. It involved immersing standard industrial grades of graphite in the molten salt, within stainless steel containers for 30 days at temperatures above 750 degrees Celsius.

The company's FLEX molten salt reactor is designed to operate at that temperature and the aim is to use commercially available graphite, which would make mass production of FLEX reactors easier, while keeping costs lower.

The research paper says: "For thermal spectrum Molten Salt Reactors (MSRs), graphite is typically utilised as moderator, reflector, and part of the core support structures. The inherent porosity within the graphite means that it is prone to infiltration by the molten salt, resulting in changes in its properties. Such property changes must be taken into consideration during reactor design and a good understanding of interaction between molten salt and the graphite microstructure is therefore important in selecting graphite grades for applications in MSRs.

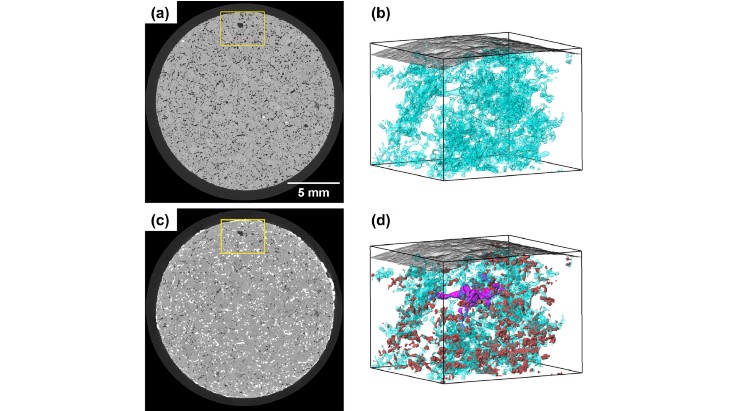

"The graphite/molten salt interaction has traditionally been investigated using the weight gain after salt infiltration, followed by mercury intrusion porosimetry and post-mortem microstructure characterisations using, for example, Scanning Electron Microscopy. The results provided an overall description to the infiltration of molten salt into the graphite porosity. However, a more fundamental understanding of the graphite/molten salt interaction is still needed. How the pore size, shape, connectivity, and location with respect to the molten salt affect the detailed salt infiltration process remains to be understood."

It adds that the system used in the research, a non-destructive 3D microstructure characterisation technique, "can potentially deliver more detailed information for understanding the graphite/molten salt interaction" with the work aiming to observe the microstructure change due to the salt infiltration.

It says that the research was able to provide "a direct comparison of the graphite's microstructure before and after molten salt infiltration, enabling the relative volume of pores that have been filled by the salt to be quantified ... [and] delivered detailed information about the spatial distribution of the infiltrated salt and the 3D structures of the infiltrated salt. All of this provides valuable information for the understanding of the kinetics that control the molten salt infiltration into the porous graphite."

Ciara Fox, MoltexFLEX senior metallurgist, said: "The results were very much as we predicted. This research is a very promising first stage on the path to predicting and controlling the behaviour of molten salt infiltration within the graphite. It’s an important stepping stone in developing a technique that will allow us to do that."

MoltexFLEX has been working with the Nuclear Graphite Research Group team led by Professor Abbie Jones on graphite-related research for three years.

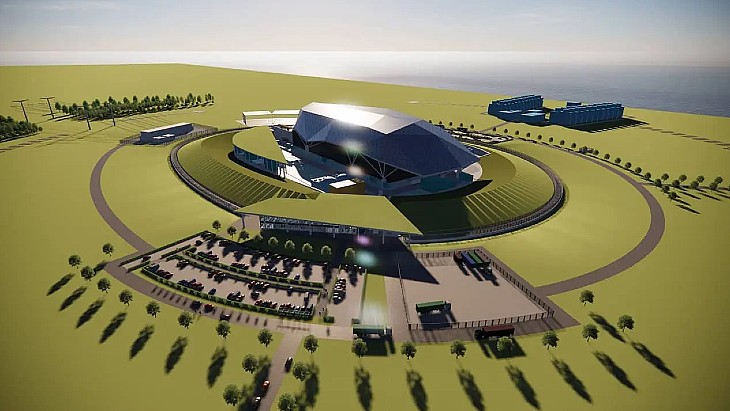

MoltexFLEX, a subsidiary of Moltex Energy Limited, is developing the FLEX reactor - the thermal neutron (moderated) version of Moltex Energy's stable salt reactor technology. The aim for the 60 MWt/24 MWe reactors is for them to be small and modular, passively safe, have no moving parts and, using 5% low-enriched uranium, have a five-year refuelling cycle. The target is to have the first reactor operational by 2029.

In May 2021, the Canadian Nuclear Safety Commission completed the first phase of the pre-licensing vendor design review for Moltex Energy's 300 MWe Stable Salt Reactor - Wasteburner (SSR-W 300) small modular reactor. The SSR-W is a molten salt reactor that uses nuclear waste as fuel. The company aims to deploy its first such reactor at the Point Lepreau site in New Brunswick by the early 2030s.

_92619.jpg)

_84504.jpg)

..._58412.jpg)