Preliminary design R&D completed for Russian molten salt research reactor

The MCC said the creation of the preliminary design was the "next step" towards creating the molten salt research reactor (IZhSR), which is intended to "allow us to develop key technological solutions for the transmutation of minor actinides, master molten salt technology and subsequently create a full-scale molten salt reactor, which will allow us to utilise minor actinides - the most dangerous component of nuclear waste from used fuel reprocessing, as they are highly radioactive and toxic, emit a large amount of heat and have a long half-life".

It added: "If you learn how to burn them (minor actinides), the period of danger will be significantly shortened and will provide a multiple reduction in waste to be buried in deep geological formations, and in the medium term will make it possible to implement the option of a less complex near-surface disposal of waste that no longer contains minor actinides."

The project, which involves a range of different organisations within Rosatom, is targeting a licence for construction in 2027 and a launch in 2031. The research and development work is due to be reviewed at a meeting within the first three months of this year.

The IZhSR project plans to use circulating molten salt fuel. It is part of the wider Russian federal project to develop "new materials and technologies for advanced energy systems" and part of the country's goal of closing the fuel cycle. Rosatom says that the period of potential danger from minor actinides can be reduced from 10,000 years to 300 as a result of the process.

Evgeniy Vlasenko, chief specialist of the development project management group, said: "With every problem solved our level of competence grows. A large amount of research work has been carried out and continues to be carried out, to justify all the decisions included in the preliminary design. MCC performs many of them on its own. The MCC's International Center for Engineering Competence develops technologies for the preparation of fluoride salts and fuel additives, verifies and certifies analytical methods for controlling their quality, and studies the physicochemical properties of salts. In the chief mechanic’s department, they are developing technologies for welding structural material - chromium-nickel alloy, which has not yet been used in the manufacture of reactors in Russia."

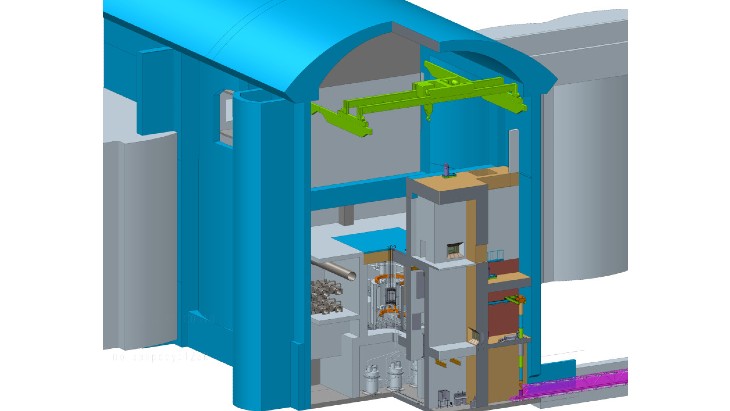

_92619.jpg)

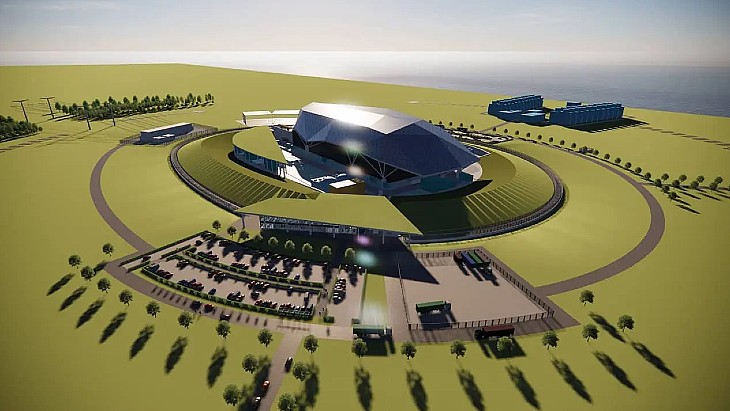

_84504.jpg)

_88592.jpg)