Prototype machine demonstrates plasma compression

.jpg)

The plasma compression prototype drives a forceful, but precisely shaped, symmetric collapse of a large liquid vortex cavity in tens of milliseconds.

"Driving a rapid, smooth, and spherically shaped collapse of a cavity created inside a rotating liquid has been a difficult engineering challenge that General Fusion has now demonstrated in this prototype machine," the company said.

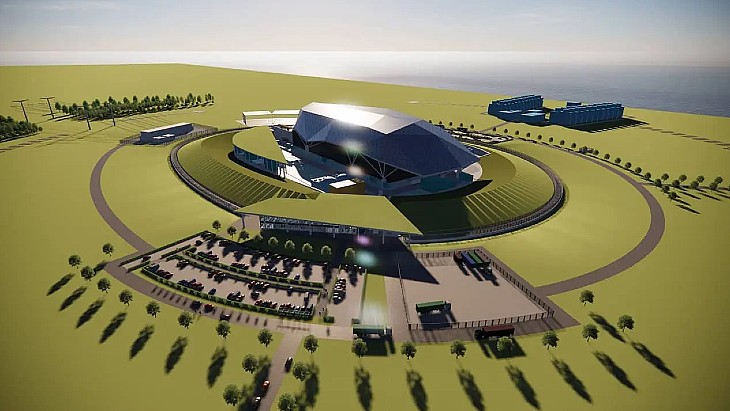

The FDP, which is to be built at the UKAEA's Culham Campus near Oxford in the UK, will use a collapsing liquid metal cavity to heat and compress plasma fuel to fusion conditions at 100 million degrees Celsius. The forces involved in its compression system will be "immense", the company says. The plasma compression prototype's milestone achievement "significantly reduces engineering and technical risks" for the demonstration plant.

MTF involves injecting hydrogen plasma into a liquid metal sphere, where it is compressed and heated so that fusion occurs. The idea of using a collapsing liquid metal cavity to create fusion has been around for decades, General Fusion said. It is using new enabling technologies such as high-speed digital control systems, additive manufacturing and advanced composite materials to make the concept viable and to de-risk its implementation.

"Net energy production is essential, but not really the ultimate goal of commercialising fusion energy, which is building economical, carbon-free fusion power plants," said General Fusion CEO Christofer Mowry. "The successful performance of this important prototype validates we are on the path to success," he added.

Construction of the FDP, which will pave the way for a commercial pilot plant using MTF technology, is to begin this year. The FDP will create fusion conditions in a "power-plant relevant" environment, proving the viability of the MTF technology, but will not be used to produce power. Global Fusion has previously said its goal is to bring fusion energy to the world by the early 2030s.

_92619.jpg)

_84504.jpg)

..._58412.jpg)