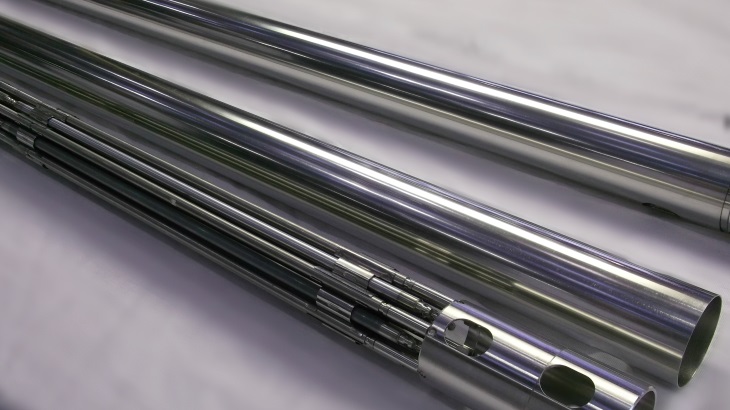

Each fuel assembly contains 24 fuel elements with four various combinations of cladding and fuel matrix materials. Fuel pellets were made from traditional uranium dioxide, as well as uranium-molybdenum alloy with increased density and thermal conductivity. Either zirconium alloy with a chromium coating or chromium-nickel alloy were used as the rod cladding material.

After each irradiation cycle, several fuel rods from each fuel assembly were extracted for further post-irradiation studies, and the new non-irradiated samples were installed instead. All the irradiated fuel rods remain hermetically sealed.

Meanwhile, the Bochvar Institue, a research facility of Rosatom's nuclear fuel manufacturer subsidiary, has started a project to develop fabrication technology for uranium disilicide pellets (U3Si2) as another option for the ATF fuel matrix. An experimental U3Si2 ingot has been manufactured for the further production of powder and pellets.

This new parallel research into ATF is informed by the advantages of uranium disilicide, said Alexander Ugryumov, vice president for research, development and quality at TVEL.

"First, it has a high density of uranium content, which may enable the introduction of longer fuel cycles without increasing the enrichment level.Second, it has high thermal conductivity and low heat capacity, which means less accumulated heat in the reactor core and lower temperature of the rod claddings. And third, the lower operating temperature may improve the performance characteristics of the fuel in general," he said.

ATF is nuclear fuel designed to be resistant to severe beyond-design basis accidents when there is a loss of coolant in a reactor.

_97013.jpg)