Howden products are proven components in the nuclear industry and have for decades been deployed in a variety of reactor designs including pressurised water reactors and advanced gas-cooled reactors, USNC said.

"Our contract with Howden is a strategic investment that marries the inherent safety of our MMR with proven equipment that will make the overall system simpler, less expensive, and more reliable," USNC-Power President Mark Mitchell said.

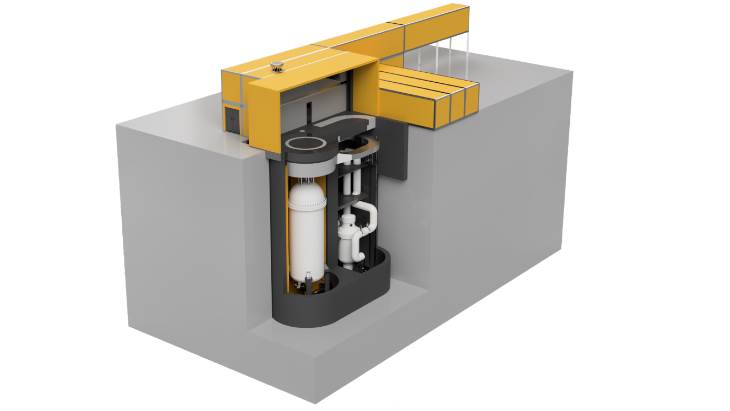

The MMR energy system consists of two plants: a nuclear plant, which contains the MMR reactors, and an adjacent power plant, which converts heat from the reactors to electricity or process heat as required. The system is designed to be uniquely simple, with minimal operations and maintenance requirements, and no on-site fuel storage, handling, or processing, USNC said. The reactor is a 15 MW thermal, 5 MW electrical high-temperature gas-cooled reactor, using USNC's Fully Ceramic Microencapsulated fuel with helium gas as the coolant. Multiple MMR reactors can be linked together to provide between 5 MW and 50 MW of electricity, up to 150 MW of heat, or a combination of the two.

The MMR is in the third stage of Canadian Nuclear Laboratories' four-stage process to site a demonstration small modular reactor at the Chalk River Laboratories site in Ontario. USNC said it will collaborate with Howden's engineering and design team to maximise heat-transfer efficiencies and plans to incorporate the Howden submerged blower into the MMR project at Chalk River.

_15863.jpg)