Tokamak Energy magnet technology to be tested in USA

.jpg)

The Oxfordshire-based company said that creating fusion energy requires strong magnetic fields to confine and control hydrogen fuel, which becomes a plasma several times hotter than the Sun inside a tokamak. Although most radiation from high-energy plasma neutrons will be absorbed by the tokamak's shielding, the magnets must be able to withstand secondary gamma rays to maintain efficient power plant operations.

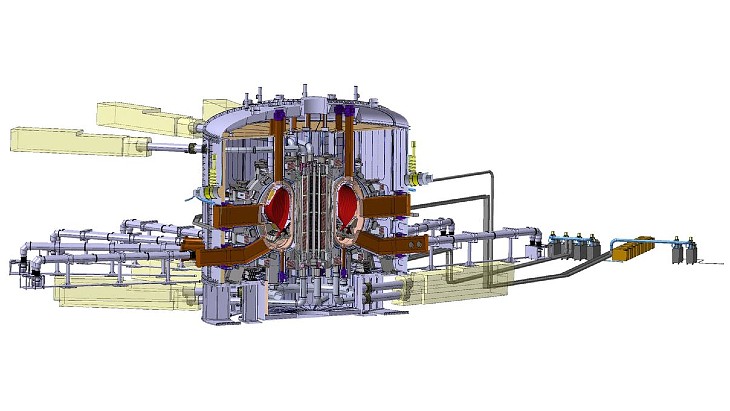

Tokamak Energy built and commissioned its specialist gamma radiation cryostat system - a vacuum device to provide thermal insulation for the magnets - as part of its mission to deliver fusion power in the 2030s.

It said that test system will now be disassembled, shipped and rebuilt at the Gamma Irradiation Facility (GIF) based at Sandia Laboratories, which is one of the few places in the world capable of housing the system while exposing Tokamak Energy's high temperature superconducting (HTS) magnets to a power plant representative dose rates - sufficient in intensity and energy - of gamma radiation.

Research and analysis on sets of individual magnets will run for six months at the New Mexico facility, which is so powerful it can do a 60-year lifetime test in just two weeks.

"Our pioneering magnet technology must withstand extreme conditions to keep fusion power plants running in the future," said Rod Bateman, HTS Magnet Development Manager at Tokamak Energy. "The specialist Sandia Laboratory is ideally configured to test magnet durability and performance when exposed to gamma radiation. It is essential to push the boundaries now as we scale up our operations towards commercial fusion."

Don Hanson, GIF Facility Supervisor at Sandia National Laboratory, added: "The GIF is a unique facility that can provide high doses of gamma radiation to large test objects. We look forward to working with Tokamak Energy to advance fusion technologies."

In February, Tokamak Energy announced it had built a world-first set of new generation HTS magnets to be assembled and tested in fusion power plant-relevant scenarios. Its new Demo4 facility consists of 44 individual magnetic coils manufactured using 38 kilometres of ground-breaking HTS tape, which carries currents with zero electrical resistance and requires five times less cooling power than traditional superconducting materials.

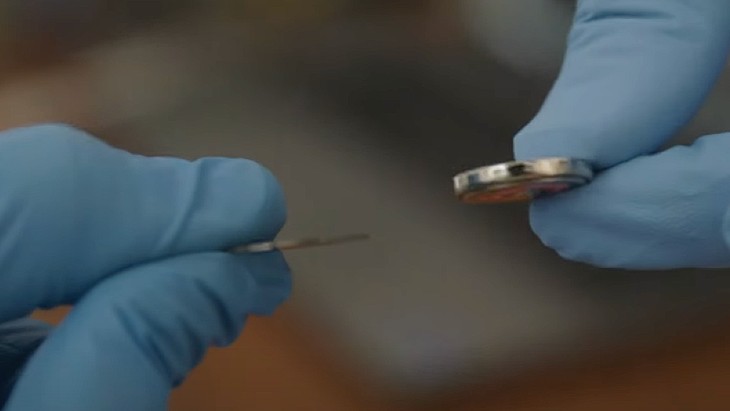

The HTS tapes are multi-layered conductors made mostly of strong and conductive metals, but with a crucial internal coating of 'rare earth barium copper oxide' (REBCO) superconducting material. The tapes are typically 12mm wide and less than 0.1 mm thick, with REBCO deposited as a thin coating. When wound into coils, HTS tapes can generate much higher magnetic fields than conventional superconducting magnets, while taking up far less space and requiring far less cooling power.

Tokamak Energy's roadmap is for commercial fusion power plants deployed in the mid-2030s. To get there the plan is for completion of ST80-HTS in 2026 "to demonstrate the full potential of high temperature superconducting magnets" and to inform the design of its fusion pilot plant, ST-E1, which is slated to demonstrate the capability to deliver electricity - producing up to 200 MW of net electrical power - in the early 2030s.

In January, Tokamak said it had signed an agreement with Japan's Furukawa Electric to supply "several hundred kilometres" of HTS tape for its ST80-HTS prototype fusion device. The HTS tape has been developed and is being supplied by Furukawa, with the production of the tape under way at the group's SuperPower Inc's site in New York in the USA.

_50521.jpg)