Additive technologies - such as 3D printing where objects are "printed" by building up material layer by layer - allow the production of parts and components that are difficult to manufacture using traditional methods using casting and mechanical processing. In addition, 3D printing allows you to reduce the weight of products, optimise the materials used and reduce production times, Rosatom says.

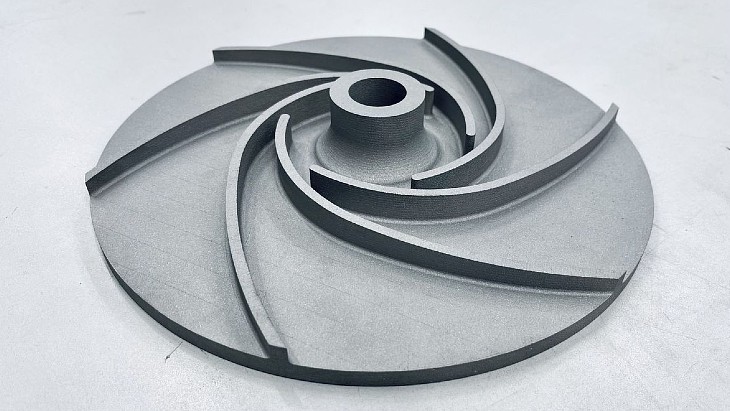

It said that in this case "the product had to have a strictly defined shape with bends. The required accuracy of the finished part's compliance with the original three-dimensional model was achieved, because it affects the performance and energy efficiency of the pump unit and the entire equipment complex as a whole. The use of three-dimensional printing made it possible to increase the strength and reduce the weight of the part".

Ilya Kavelashvili, director of the Additive Technologies business line in TVEL, said: "This is the first case of using a product manufactured using 3D printing at a nuclear facility, which will be another confirmation of the high quality and reliability of additive manufacturing of parts and components. Rosatom is carrying out comprehensive work on the implementation of additive technologies in the nuclear industry. Our working group includes more than 60 chief designers, end users, metrologists, and representatives of certification bodies.

"A list of 120 parts that can be printed on 3D printers has been prepared. We have selected 10 samples of different safety classes from them, which will be reference. Among them are an anti-debris filter for a fuel assembly, a baffle for the internal device of a VVER-TOI nuclear reactor, and others. During the tests, we will prove that they are reliable for industrial use, and this will form the basis for the regulatory framework for the use of additive technologies in the nuclear industry."

Rosatom says it is both a supplier and customer for additive technology development with a regional network of centres with such capacity being developed.

The International Atomic Energy Agency sees considerable potential for 3D printing of parts in the nuclear energy sector, with the first use case being a 3D-printed impeller installed at a Slovenian reactor in 2017, while Oak Ridge National Laboratory printed brackets called channel fasteners which were installed in a nuclear power reactor in 2021, and Framatome installed the first 3D-printed stainless steel fuel component at the Forsmark nuclear power plant in Sweden in 2022. As well as Russia, other countries including South Korea are also using 3D printing to manufacture items.