NuScale, ORNL to assess SMR use by industry

.jpg)

The study will be based on process data from a US chemical facility to help the plant meet its electric power and process steam requirements with NuScale's small modular reactor (SMR) technology.

The TEA will evaluate the viability of NuScale's SMR technology with steam heat augmentation for use in a chemical system, including examination of steam reliability, operational costs and system stability. It will also study SMR siting suitability.

"This work will be a highly collaborative effort with engineers from ORNL and NuScale forming a composite engineering team," NuScale said. "The proposed deliverables of the techno-economic assessment are anticipated to be completed within one year."

The TEA is receiving funding through an award granted by the Department of Energy's Gateway for Accelerated Innovation in Nuclear (GAIN) initiative, which connects industry with the US national laboratories to accelerate the development and commercialisation of advanced nuclear technologies. Funding for the project was announced in September, in the fourth round of GAIN Vouchers awarded in fiscal year 2023.

"With the support of the US DOE under the GAIN initiative, we are thrilled to collaborate with Oak Ridge National Lab to assess this exciting new decarbonisation pathway that serves as a model for chemical plants," said NuScale President and CEO John Hopkins. "It is a crucial step in the transition to a sustainable future that serves all energy-intensive sectors. As the first and only US Nuclear Regulatory Commission certified SMR design, NuScale leads in the development of new technologies to achieve industry-wide decarbonisation."

"Nuclear technologies will play an essential role in the carbon-free integrated energy systems of the future," said Mickey Wade, Associate Lab Director for Fusion and Fission Energy and Science at ORNL. "The reliability of heat production from advanced fission technologies will drive deep decarbonisation across industrial sectors, including chemical production facilities. ORNL's expertise in techno-economic analysis regarding system reliability, operational cost, and system stability analyses provides an enabling foundation for our partners to evaluate this decarbonisation pathway."

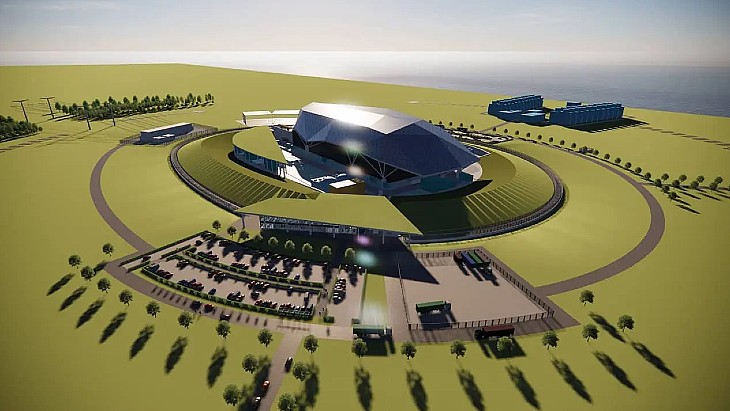

The NuScale Power Module on which VOYGR nuclear power plants are based is a pressurised water reactor with all the components for steam generation and heat exchange incorporated into a single 77 MWe unit. The company offers a 12-module VOYGR-12 power plant is capable of generating 924 MWe as well as the four-module VOYGR-4 (308 MWe) and six-module VOYGR-6 (462 MWe) plants and other configurations based on customer needs.

A pilot six-module plant had been planned to be built near Idaho Falls in the USA as the Utah Associated Municipal Power Systems (UAMPS)-led Carbon Free Power Project, expected to be operational by 2030. However, UAMPS and NuScale earlier this month announced they had mutually agreed to terminate the project.

In May, NuScale said new research demonstrates the advanced capabilities of its SMRs for reducing emissions in industrial sectors. Led by NuScale co-founder and Chief Technology Officer José Reyes, the benchmarked research found that NuScale SMRs have the potential for use in a wide variety of high-temperature industrial processes not previously envisioned using light water reactor (LWR) technology.

The company's research showed that the steam generated by a single NuScale Power Module can be compressed and heated to produce process steam at commercial scale, temperatures and pressures. Reyes and his team found that a single Power Module, generating 250 MWt, can produce more than 500,000 lb/hr of steam at 1500 psia and 500ºC, with the potential to extend production to 2400 psia and over 650ºC.

_92619.jpg)

_84504.jpg)

_88592.jpg)