The project involves work with electrorefining technology to recycle fuel for use in advanced fission power plants, Oklo said. Commercialising the technology will help reduce fuel costs for advanced fission, while reducing supply chain risks.

The partnership is an outcome of a cost-share project awarded by the Department of Energy's Technology Commercialisation Fund (TCF) that leverages R&D funding in applied energy programmes to mature promising energy technologies with the potential for high impact.

The TCF last year awarded more than USD30 million in federal funding, matched by more than USD35 million in private sector funds, for a total of 68 projects across 12 national labs. Oklo said it is matching DOE funding to Argonne for the project.

"This partnership with Argonne will help reduce fuel costs for advanced reactors, and therefore overall costs for power from advanced fission," Oklo CEO Jacob DeWitte said.

"There are tremendous energy reserves in used fuel that can provide emission-free power for entire nations for centuries while reducing the volume and radiological lifetime of waste material."

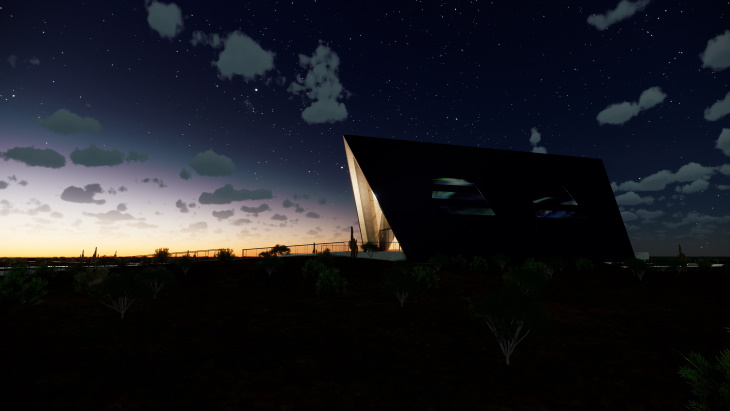

Oklo's proposed Aurora reactor design is a fast neutron reactor that uses heat pipes to transport heat from the reactor core to a supercritical carbon dioxide power conversion system to generate electricity. Using metallic high assay low-enriched uranium, or HALEU, fuel, the Aurora 'powerhouse' produces about 1.5 MWe and can also produce usable heat.

The DOE has issued a site use permit for a unit to be built at the Idaho National Laboratory, and the US Nuclear Regulatory Commission (NRC) in June 2020 accepted for review Oklo's combined licence application (COLA) for the plant, although the regulator in January this year said it had not received sufficient information to move forward with its review.

Oklo has recently said it is discussing next steps with the regulator, and is continuing its work on advanced fission "as key to a clean energy future".

_55401.png)

_23009.jpg)